Single phase motors are a type of electric motor that operates on single phase electrical power, which is a power source in which all of the voltages of the power supply work in unison as a single unit, functioning to distribute alternating current (AC) power. One industry that utilizes single phase motors is construction, which uses them to power essential building equipment such as electric power tools and portable lighting.

Single phase electrical power works much like a three phase electric power, in which the voltages of the power supply can alternate between three different circuit conductors, except with the single it is on power supply providing the voltage. Therefore 3 phase motors are able to self-start and produce a rotating magnetic field by itself, whereas single phase motors require the use of an additional power supply in order to start and produce the magnetic field. Three phase motors are more commonly found in industrial manufacturing applications; however, single phase motors are also utilized in a wide range of applications and industries including: residential, for use in household appliances such as dishwashers, washing machines, blenders, dryers and more; commercial, for use in equipment and parts such as fans, swimming pool pumps and air conditioners; industrial, in small workshops used to power smaller-horsepower (HP), lighter-duty machine tools such as gear motors; and aerospace, for use in smaller power, motion control applications.

Since single phase motors are incapable of producing a rotating magnetic field on their own, they require an external power supply in order to produce power and effectively convert electrical energy into mechanical energy. A common external power supply used to start single phase motors is an assembly of a combination of either a capacitor and an auxiliary winding, which is also known as a start switch and actually is a seconding winding in the motor itself. Another combination could be that of a capacitor, an auxiliary stating winding and a centrifugal switch. Through the external power supply, an AC current is applied to the single phase motor. When the AC current is applied, both the start winding and the run winding function to produce magnetic fields. Of the two windings, the start winding has a much stronger current and as a result, a stronger magnetic field is created which causes the motor to begin rotation. It is only when the motor reaches the point of about 80% of its rated speed that the centrifugal switch is activated and disconnects the start winding from the motor. Once the start winding is disconnected, the motor is able to main a strong enough rotating magnetic field that it is able to operate on its own without the external power supply.

At divine machine tools, we manufacture, supply and export high-quality single phase electric motors to help our customers power their machines. Our motors are built to last, with a focus on efficiency, reliability, and long-life. We offer two types of motors, one for high-speed applications and one for heavy-duty applications. Our motors are manufactured in our ISO-certified facility in India.

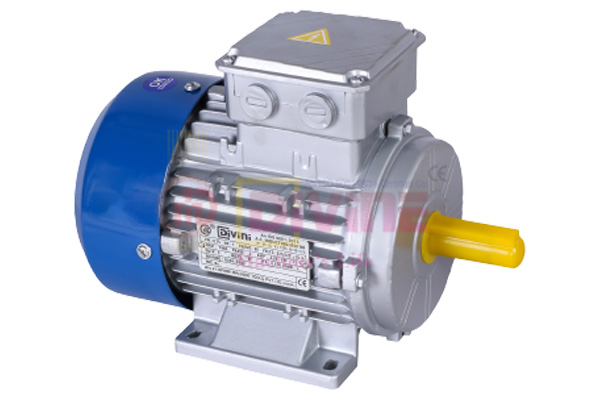

SINGLE PHASE B3 MOUNTING MOTOR

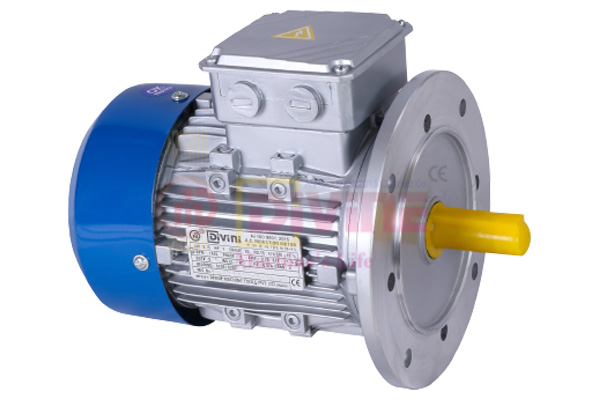

SINGLE PHASE B5 MOUNTING MOTOR

FOOT MOUNTING MOTOR

FLANGE MOUNTING MOTOR

Range of Product

Single phase motor manufacturing from 0.25 HP to 3.0 HP (0.18KW to 2.20 KW) frame 63 to 112m in 2 & 4 hole.

Mounting Type

- FOOT (B3)

- FLANGE (B5)

- FACE (B14)

- FOOT/FLANGE(B35)

- FOOT/FACE(B34)

Frame

Single phase motor are supplied in a seat medal body and robust, rugged cast iron frame with integral feet. On request we can supply motor in aluminum body up to 100L frame.

Voltage and Frequency

Simple phase motor are supply volts 220 +5% 1 phase 50 Hz +3% we are also able to supply motors in 110 volts on Hz 60 also

Insulation

Single phase motor supply with B class insulation as standard features. Also supply “F” on request of customer.

Protection

We are supply motor with ingress protection 44 as defined in IS:4691. Motors can be supplied with IP-54 and IP-55 on request.

Shaft Direction

All single phase motor are supply with clock wise shaft rotation it also possible of reverse direction rotation. We are manufacture single reverse single phase motor.

Shaft & Rotor

Single phase motor rotor is positive locking with shaft key joint so that cannot move on high full load torque. Shaft are made by EN-8 or EN-9 material. Single phase motor rotor are use of high pressure e.c. grad aluminum die-cast. Every motor is dynamically balanced. It make motor low amplitudes of vrbration and noise

Painting and Lubrication

Single phase motor bearing are adequate lubricated with lithium based high temp up to 150 deg. All the motor are supplied with C3 ball bearing and fully charged with lithium base grease at the time of assembly.

Enclosure

Single phase motor supply with enclosure T.E.F.C. (Totally Enclosed fan coiling)

Terminal Box

All single phase motor supplied with Terminal box on top position for foot mounted (b3)

Paints

All single phase motor are painted with Semi glossy synthetic enamel paint. However Sp. Paint is available on request.

Features

- High efficient

- Noise free

- Vibrating free

- Low Running cost

- Durable

- Smooth finishing

- Cost effective

- Precision design

Single Phase Induction Motor- All About Circuits | Single Phase AC Induction Motor | Single Phase Electric Induction Motor | Single Phase Motor Manufacturers, Exporters And Suppliers | Foot Mounting Electric Motor | Flange Mounting Electrical Motor